Service is very important to us. Whether it is about counseling or it is about supporting our customers in the project phase. Our many years of extensive experience in a wide variety of industries and the numerous possible applications of our rolls offer our customers and their components a real added value. We are at your side as a reliable partner.

- Grinding of rolls at ambient temperature

- Hot grinding of rolls at operating temperature

- Grinding in mounted bearings and housings

- Coating with e.g. chrome, nickel, ceramics, tungsten carbide and anti-adhesives

- Three-dimensional milling on 5-axle-machining-centres

- Internal cleaning and rinsing of rolls

- Repairing of bearing seats by means of chrome plating or with thermal spray coatings

- Repairing of journals and changing of journals

- Refinishing embossed rolls

- All kinds of repairs of rolls

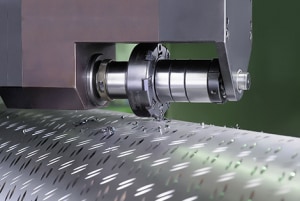

Milling of bulb and checker designs for steel and aluminum industry

Milling of bulb and checker designs for steel and aluminum industry Fluting of rolls from flour milling, feed production and oil milling.

Fluting of rolls from flour milling, feed production and oil milling.

In order to achieve the highest precision, permanently installed automatic measuring systems are used for concentricity and shape control.

In order to achieve the highest precision, permanently installed automatic measuring systems are used for concentricity and shape control.

On CNC grinding machines with the latest control technology and a wide variety of grinding wheels for different surfaces and materials, we grind cylindrical, crowned, hollow and special shapes (CVC) for our customers.

On CNC grinding machines with the latest control technology and a wide variety of grinding wheels for different surfaces and materials, we grind cylindrical, crowned, hollow and special shapes (CVC) for our customers.