Competence through tradition

Competence through tradition

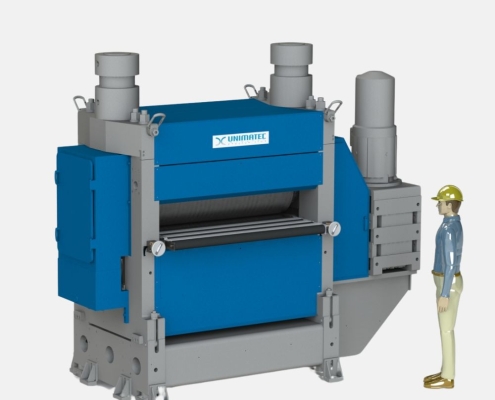

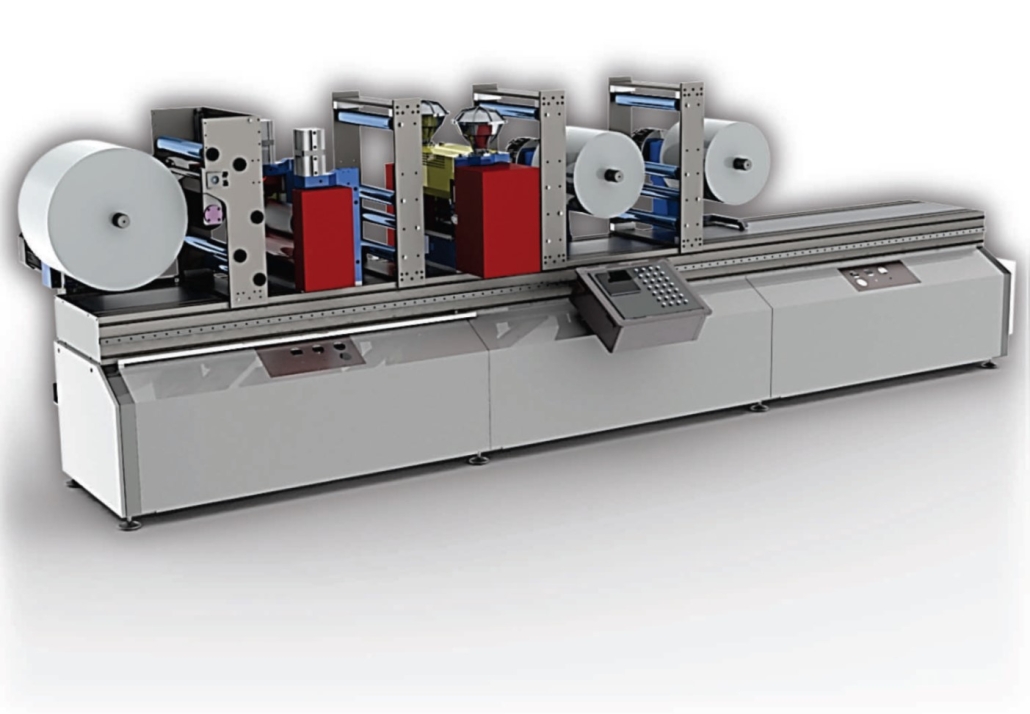

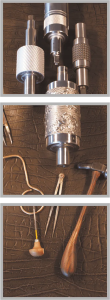

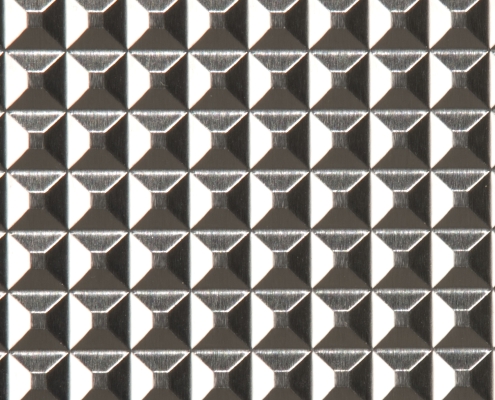

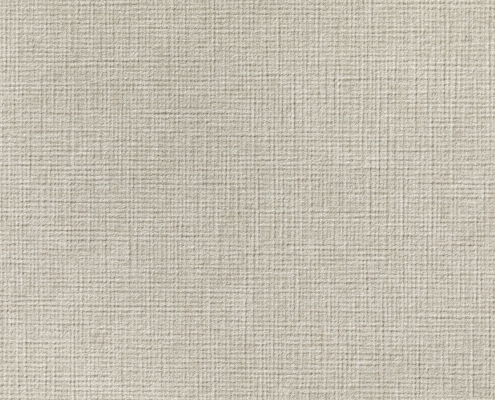

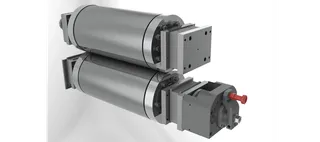

We have an agency representing UNIMATEC, a leading German manufacturer of embossing machines and rollers.

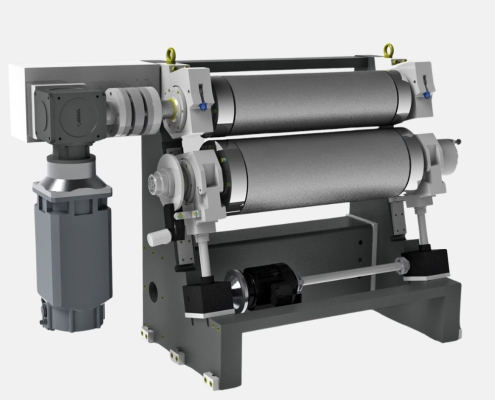

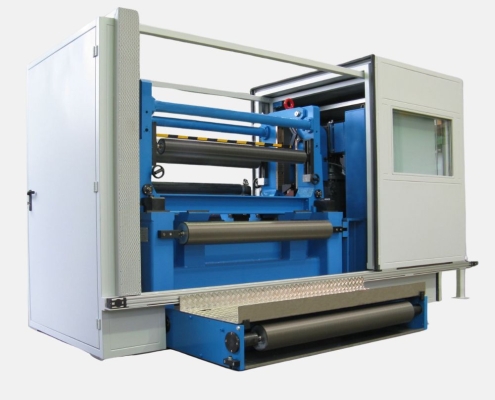

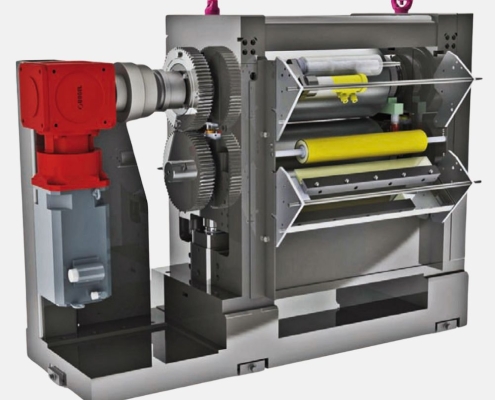

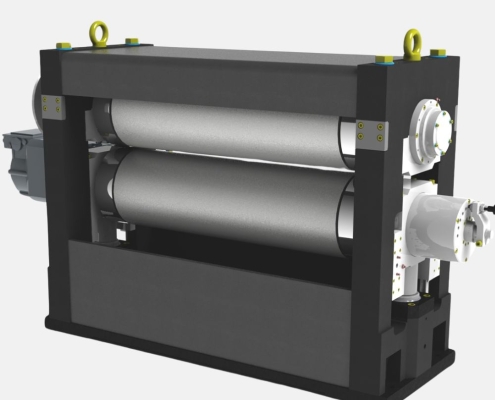

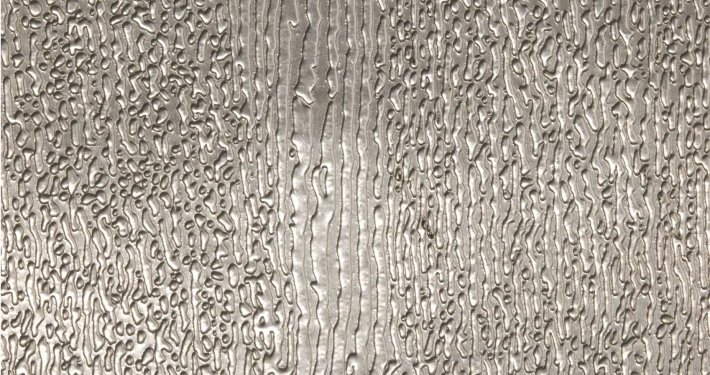

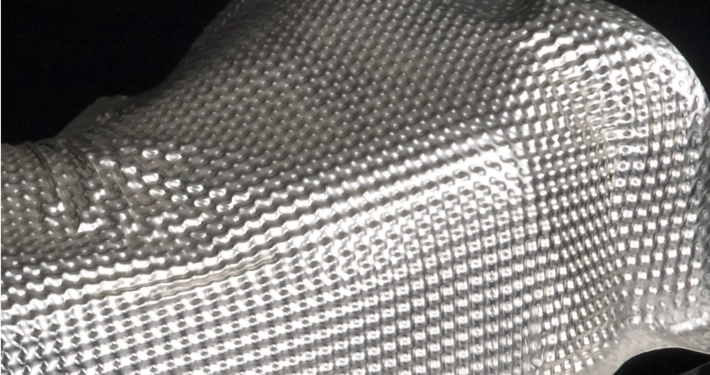

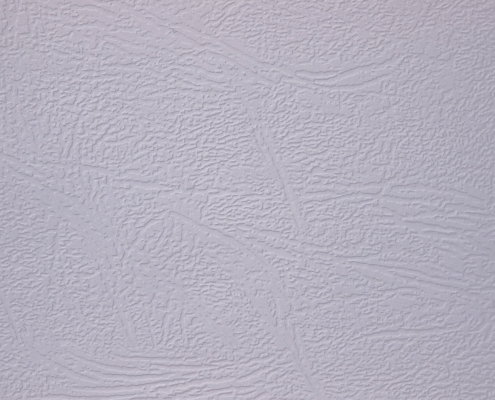

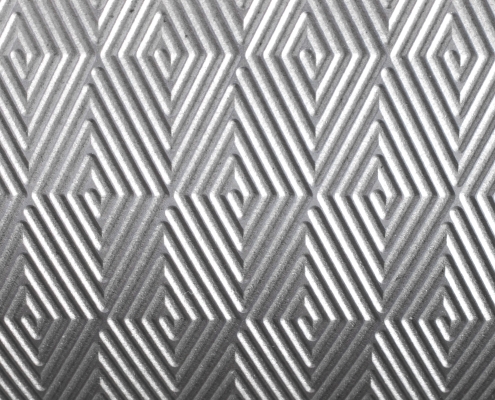

UNIMATEC designs, manufactures, and installs high-quality embossing machines, rollers, and sets.

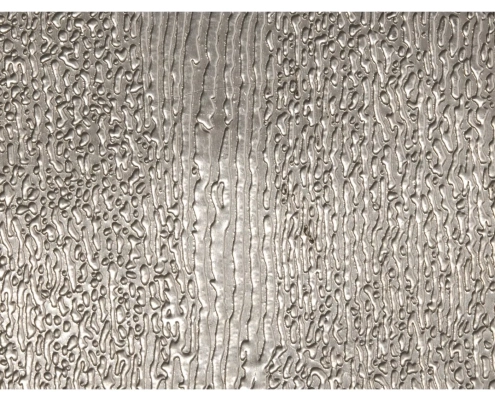

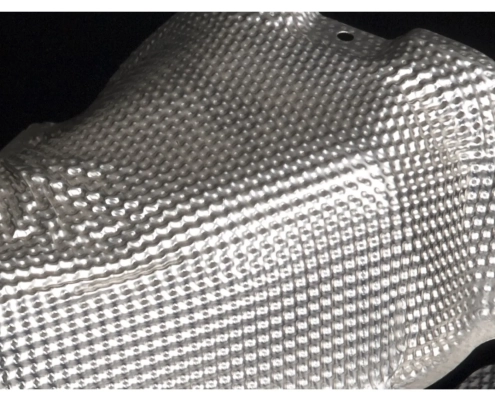

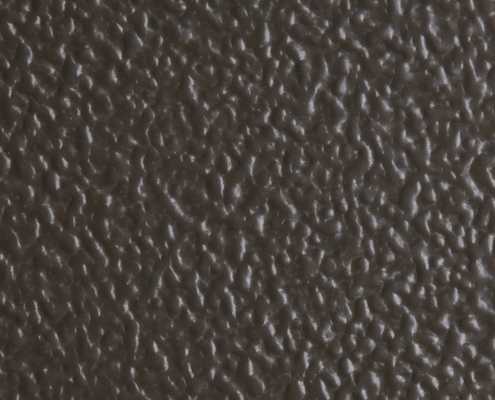

Our machines and rollers meet the requirements of various industries, such as textile, paper, metal, plastic, leather, and aluminum.

Thanks to intensive and open communication with our customers, we are able to find a tailor-made solution for every individual application.

Contact us to discuss your custom requirements.

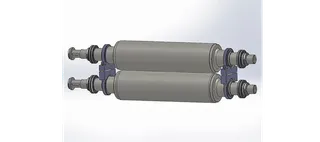

1. Compensation of Load Alternation

1. Compensation of Load Alternation 2. Quick adjustment

2. Quick adjustment 3. Multi Stage Nip Selector

3. Multi Stage Nip Selector