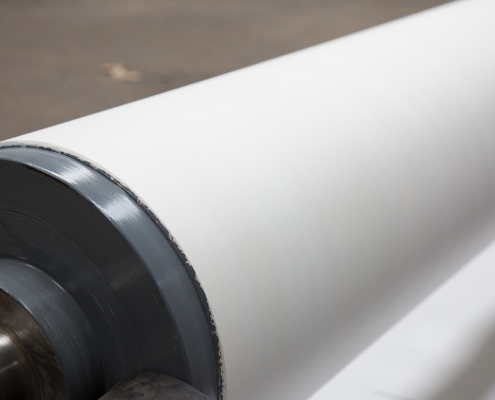

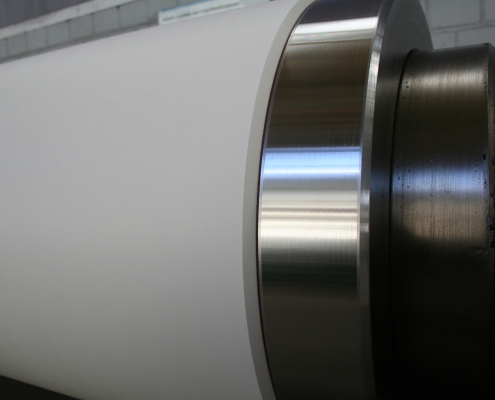

Together with our partner and manufacturer KWF Hilger, we offer various types of squeeze rolls, primarily used in the textile industry. These rolls are designed to efficiently remove liquids from woven, knitted, and non-woven fabrics, as well as from fibers.

Our squeeze rolls come with specific construction and operational benefits, such as enhanced squeezing effects, reduced energy consumption, lower maintenance costs, and decreased chemical usage.