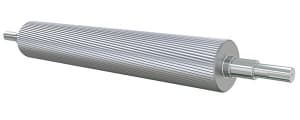

Cracking rolls are used to break the product. These rollers are mainly used in crushing mills, the animal feed industry and the oilseed industry. The wear resistance increases the economic efficiency of the machining process. Additional advantages of these high quality rollers are longer maintenance intervals, lower repair costs and lower energy consumption. The better the quality of the roll material and the more precise the roll geometry, the better and more uniform the quality of the product.

Cracking rolls are used to break the product. These rollers are mainly used in crushing mills, the animal feed industry and the oilseed industry. The wear resistance increases the economic efficiency of the machining process. Additional advantages of these high quality rollers are longer maintenance intervals, lower repair costs and lower energy consumption. The better the quality of the roll material and the more precise the roll geometry, the better and more uniform the quality of the product.