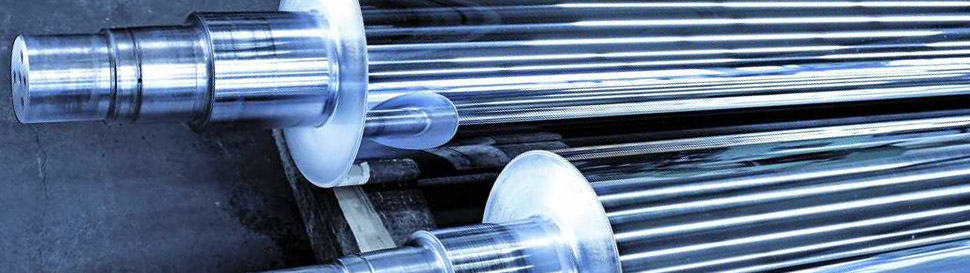

Our cylinders are perfectly manufactured and ready to use. We can produce for you cylinders for gravure, screen, lacquer, color, impression, pressure, air and offset cylinders. In addition to our high value basic cylinders, we offer expertise especially in surface treatment.

Our cylinders are perfectly manufactured and ready to use. We can produce for you cylinders for gravure, screen, lacquer, color, impression, pressure, air and offset cylinders. In addition to our high value basic cylinders, we offer expertise especially in surface treatment.

Our cylinders are used for printing on:

- Paper

- Foil

- Laminates

- Embossing

- Metal

Our solid casted printing cylinders are used for painting metal.

“The more homogenous the surface of the printing cylinder, the better the print result.”