Heat transfer rollers, cooling rollers aare used for heating and cooling of all types of sheet products. The more precise (accurate) the temperature control and the shape of the rollers, the better the properties and quality of the sheet product.

Heat transfer rollers, cooling rollers aare used for heating and cooling of all types of sheet products. The more precise (accurate) the temperature control and the shape of the rollers, the better the properties and quality of the sheet product.

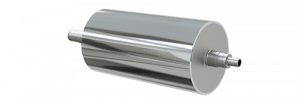

Our heat transfer & chill rolls are made by cast iron and on the basis of cylinders

Manufactured according the requested specifications

The basis of our cylinder rolls are tubes.The materials are steel, stainless steel, aluminium or combinations.

The quality of the weld seam is an important component for the quality of the cylinder. Therefore, welding is one of the core competences for cylinder construction. We place great value on this. Our partners are certified companies.

We build in this range: heating and cooling rollers, laminating rollers, calendars, printing rollers and embossing rolls, et cetera.

Standard chilled cast rolls

The casting process for chilled cast iron and grey cast iron is using the static castic proces. The horizontal centrifugal casting is used for smaller rolls.

Click here for more details about the casting processes.

In this range we built: mixing rolls, thermo rolls, calender rolls, heating and cooling rolls, laminating rolls, printing rolls, refining rolls, flaking rolls, cracking rolls and embossing rolls.

| Common diameter | 100 – 2,000 mm |

| Common roll body length | 300 – 5,000 mm |

| Material | mild steel, heat-treatable steel, stainless steel |

| Design | single shell, double shell with – displacement body – multiple helical passages – counter flow passages |

| Coating | without coating, chrome, nickel, rubber, PUR, ceramics, tungsten carbide, anti-adhesive coating |

| Surface | cylindrically ground or ground with crown, polished |

| Precision | TIR and geometrical shape ≤ 0.005 mm |

| Special features | manufacturing and inspection according to pressure equipment directive 97/23/EC possible |